Used CNC Experts

Call us at: (803) 548-8000

< Back to Lathes

Special Item

2023 OKUMA MULTUS B250II-1SW/750

OSP-P300SA-H, 2.6" Bar, 8" Chuck, 5000 RPM, 30 HP, H1 Spindle, Y-Axis, Sub Spindle, Big Bore, Touchsetter, Chip Conveyor, Pristine

Talk to a representative today!

(803) 548-8000

(803) 548-8000

Product Details

-

Chuck Size 8"

-

Max Diameter Bar Capacity 2.6"

-

Spindle Motor 30 / 20 HP

-

Spindle Speed 5000 RPM

-

Spindle Nose A2-6

-

Spindle Bore 3.15"

-

Tools 60

-

Sub Spindle Chuck Size 6"

-

Sub Spindle Motor 15 / 10 HP

-

Sub Spindle Nose 140 mm Flat

-

Sub Spindle Speed 6000 RPM

-

Rapid Traverse Rates (X & Z / Y / W) 1575 / 1023 / 787 ipm

-

X-Axis Travel 19.69"

-

Z-Axis Travel 31.5"

-

Y-Axis 7.87"

-

C-Axis Index (Left & Right Spindles) .001 Degrees

-

Distance Between Spindles 40.55"

-

H1 Index 0.001 Degrees

-

H1 Spindle Speed 50 - 12000 RPM

-

H1 Swivel 225 Degrees

-

Max Tool Diameter 3.54" / 5.12"

-

Max Tool Length 7.87"

-

Max Tool Weight 8.8 lbs.

-

Max Turning Diameter 23.62"

-

W-Axis Travel (Sub Spindle) 31.89"

Product Features

- OKUMA OSP-P200SA-H CNC Control

- 12.1" Color TFT

- USB Port

- H1 Upper Tool Spindle

- Programmable Sub Spindle

- Royal Quick Grip 52 Accu-Length Chuck

- Kitagawa 6” B206 Chuck Right

- Spindle Motor Upgrade 30 HP Left

- 60 Tool Magazine (Capto C6)

- Auto Gauging Renishaw RMP600 RMI-Q Capto C6

- Renishaw Inspection Plus Software with GUI - Lathe

- Y-Axis Gauging with Slope Gauging

- Z-Axis Auto Zero Offset Function Both Spindles

- C-Axis Auto Zero Offset Function Both Spindles

- Touchsetter Manual

- Touch Sensor Gauging Interface Renishaw RMI-Q

- Lathe Tool Index Function Multi Edge

- Chip Conveyor Right Discharge Hinge High 750

- Negative Tool Radius Compensation

- C-Axis Torque Skip Function Both Spindles

- Multi-Tap Transformer

- Remote Jog Handle

- Three Color Tower Light

- B-Axis 0.001 Degrees

- HiG Control

- PFC II

- B-Axis Compensation

- (10) Sets Work Coordinates

- (500) Sets Tool Offsets

- Lathe Tool Index

- Servo Link NC and Spindle

- One Touch IGF Advanced

- Tape Data In / Out

- Home Position B

- Plane Conversion

- Profile Generation

- Synchronized Tapping

- Helical Cutting

- Slant Cutting

- Home Position

- Spindle Fluctuate

- NC Torque Limiter

- GM Code Macro

- Center Compensation

- Lap 4

- Nose Radius 2B

- User Task 2

- Expanded Auto Chamfer

- Arc Thread Cutting

- Collision Avoidance System

- Programming Help

- 3D Animation

- Animation

- C Zero Offset

- Y Gauging

- Optical Sensor

- Pitch Error Compensation

- Tool Life Management

- Tool Wear Compensation

- Tool Offset System

- Inch/Metric Switchable

- Cycle Time Calculation

- NC Work Counter

- Cycle Time R. New

- NC Work Monitor

- Cycle Time Check

- Mac Man

- DNC T-1

- Hi-Cut Pro

- Thermal Compensation L2

- Spindle Orientation

- M-Axis Orient

- Spindle Max IL

- Coordinate Conversion

- Coordinate Calculate

- Program Message

- Custom-API

- OSP-API

- Use Tool Disposal

- Machining Mode

- Nose-R Direction Change

- Base Operating Screen

- Tool Mac Information

- Offset Base Fix

- Y-Mode Touch Setter

- Axis Active Stop

- Variable Lost Motion

- Servo Navi L

- Rapid Feed Speed Set

- Work Weight Set

- C-Axis Manual Coordinate

- C-Axis Torque Skip

- SDF Separate NC

- SDF Separate SP

- MFU

- Spindle Collision Detection

- Rotary Notch Fil

- Cycle Mode Set

- Short Rapid Droop

- Gather Aging

- Machine Diagnostics

- Eco Suite

- OSP Suite

- Thermal Compensation OilCon

- Mac Time Short

- Spindle out Monitor

- Suite Without Widget

- Remaining Time Display

- Eco Suite Plus

- Chuck Grasp Confirmation

- Oil Cooler Alarm A

- Ex Brake Release

- Spindle Orientation Electric

- First Spindle Oil Cooler

- Second Spindle Oil Cooler

- Coolant Through Spindle

- M-Axis Orientation

- B-Axis Position LOMP

- ATC Type H

- Mechanical Lock Door 1

- Override Special

- Load Monitor

- Cycle Time Re.New

- Thru and Measure Air

- Air Pressure Detection

- Program Stop Special

- Oil Level Detection

- Thru Airblow IL

- B-Panel

- OSP Chip Convere

- High Pressure Coolant Unit 3

- C-Axis Brake Torque Limiter

- First Spindle C Gain Cut

- Second Spindle C Gain Cut

- PH Type B

- Spindle Diagnostic

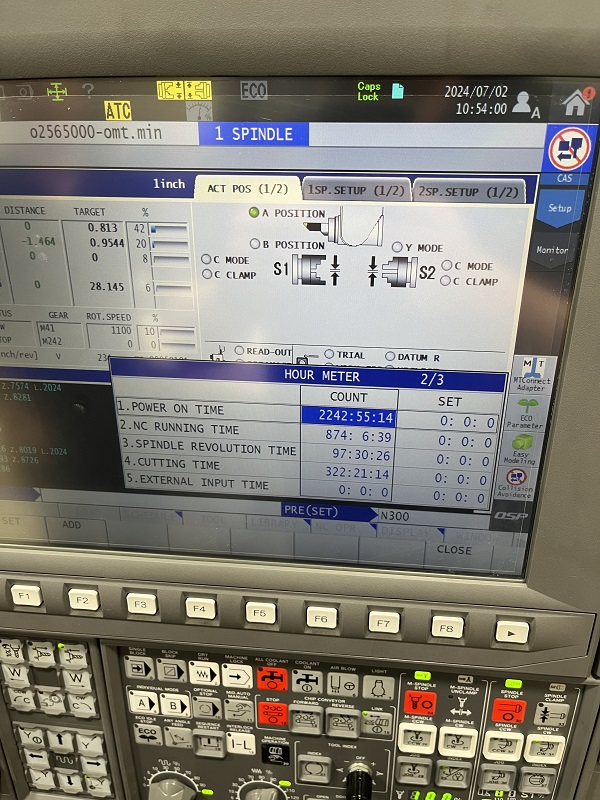

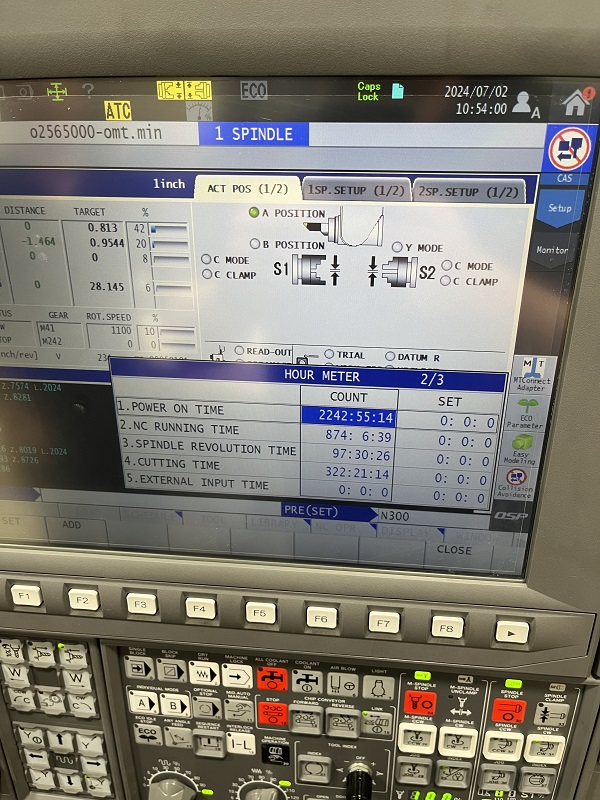

- Manufacture Date February 2023

- 2242 Power On Time

- 874 NC Running Time

- 97 Spindle Revolution Time

- 322 Cutting Time