Used CNC Experts

Call us at: (803) 548-8000

< Back to Lathes

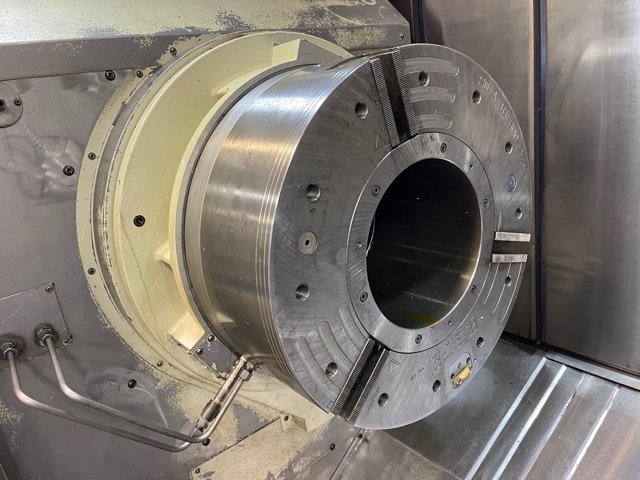

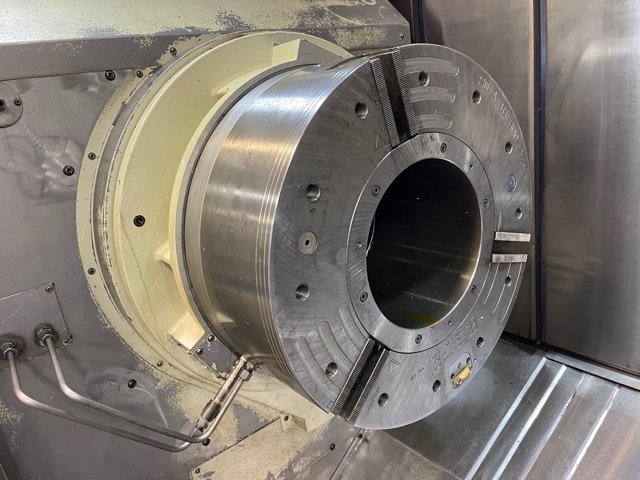

2010 OKUMA MULTUS B750-W/4000

OSP-P200L, 24" Chuck, 10.8" Bore, 41" Max Dia, 50 HP, 80 Tools, Capto C8, 2000 RPM, Y & B-Axis, Steady Rest, Long Boring Bar Attachment

Talk to a representative today!

(803) 548-8000

(803) 548-8000

Product Details

-

Chuck Size 24"

-

Max Swing Over Saddle 41.34"

-

Spindle Motor 50 / 40 HP AC

-

Spindle Speed 2000 RPM

-

Spindle Nose A2-20

-

Tools 80

-

Milling Spindle Motor 50 / 40 HP

-

Milling Spindle Speed 5000 RPM

-

Milling Spindle Torque 372 ft. lbs.

-

Rapid Traverse Rates 1575 IPM

-

X-Axis 42.52"

-

Z-Axis 165.94"

-

Y-Axis + / - 12.99"

-

C-Axis Index (L & R) .001 Degrees

-

B-Axis Travel -30 to 210 Degrees

-

Machine Weight 50,000 lbs.

-

Machine Weight 83,600 lbs.

-

Distance Between Spindles 178.9"

-

Max Tool Diameter 5.31" / 11.81"

-

Max Tool Length 23.6"

-

Max Tool Weight 66 lbs.

-

Max Turning Diameter 41.34"

-

Spindle Taper Capto C8

-

W-Axis 133.66"

Product Features

- OSP-P200L CNC Control

- 15" Color TFT

- B-Axis Upper Tool Spindle Full 5-Axis Contouring

- Twin Opposed Spindles

- Schunk Rota TB 600-275 LH Self-Contained Pneumatic 3-Jaw Chuck

- 24" Hydraulic Chuck (Right Spindle)

- 80 Tool Magazine (Capto C8)

- Through Spindle Coolant (MP Systems 1000 psi)

- SWM Autoblock Programmable Hydraulic Steady Rest

- Enomoto Chip Conveyor (Side Exit)

- (3) Long Boring Bar Attachment

- Actual Long Boring Bar with Replaceable Capto C8 Heads

- Multi-Tap Transformer

- Three Color Tower Light

- Spindle Chiller Unit

- Remote Jog Handle

- Hi-G Control

- 500 Sets of Tool Offsets

- Tape Data In/Out

- Plane Conversion

- Profile Generation

- B-Axis Interpolation

- Rigid Tapping

- Helical Cutting

- Slant Cutting

- Home Position

- Spindle Fluctuate

- NC Torque Limiter

- GM Code Macros

- Center Computation

- Touch Setter

- Touch Sensor

- Y-Axis Gauging

- Optical Sensor

- Pitch Error Compensation

- Tool Life Management

- Tool Wear Compensation

- Inch/Metric Switchable

- Cycle Time Calculation

- Cycle Time Renew

- Tool Center Control

- Super Nurbs

- Super Hi-NC

- Thermal Compensation L2

- Servo Link NC

- Lap 4

- Nose Radius 2B

- User Task 2

- Expanded Auto Chamfering

- Collision Avoidance System

- Programming Help

- 3D Animation

- NC Work Counter

- NC Work Monitor

- Cycle Time Check

- Load Monitor

- Mac Man

- DNC-T1 & T-3

- Spindle Orientation

- M-Axis Orient

- Custom API

- Machining Mode

- Axis Active Stop

- Override Special

- Load Monitor

- B-Axis .001 Degrees

- B-Axis Interpolation

- Auto Door

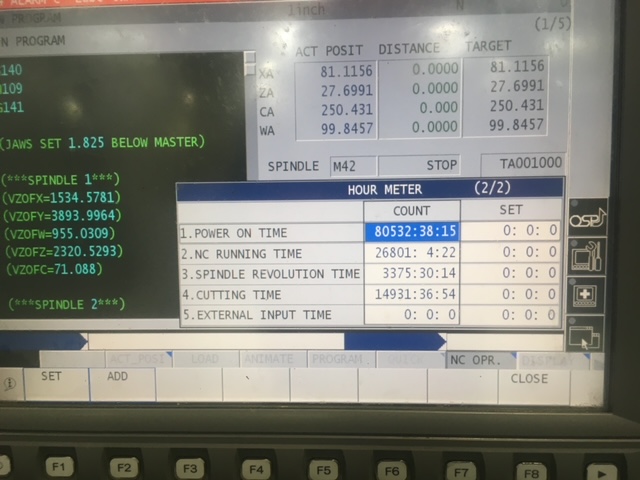

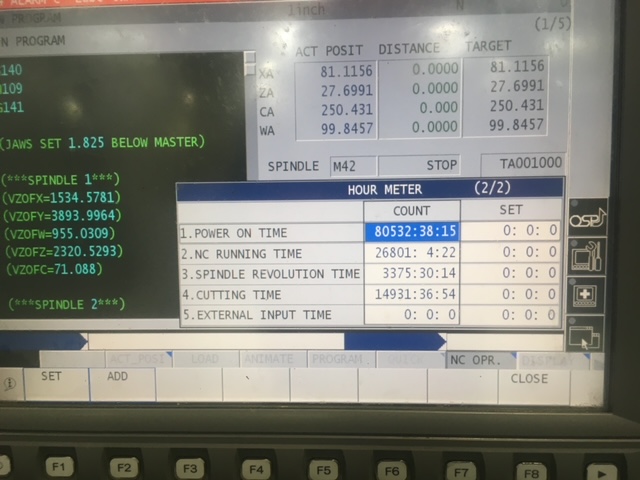

- Manufacture Date July 2010

- 80,532 Power On Time

- 26,801 NC Running Time

- 3375 Spindle Revolution Time

- 14,931 Cutting Time